At ROST-COAT, we put your crew’s safety first. Metal machinery and substrates can transmit sound and vibration that’s dangerous to working personnel, so the ROST-COAT Sound Control-dB is designed to dampen noise caused by structural translation.

ROST-COAT Sound Control-dB is easily applied with a sprayer, roller or brush—even in hard to reach places. In addition, the coating cures quickly and can be applied while equipment is functioning, so there’s no lost production time or wasted manpower.

Typical applications include:

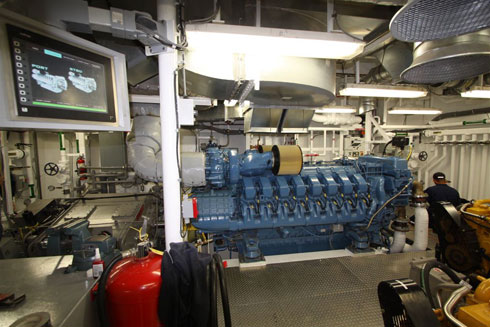

- Motors and transformers

- Metal ducts and vents

- Machine housing

- Fans, condensers and HVAC systems

- Assembly line equipment

- Mills and grinders

- Tanks and storage vessels

When you need to eliminate the noise danger caused by resonating metal, rely on the ROST-COAT Sound Control family. Requiring minimal application effort, the coatings go on quickly and last for years with little maintenance. And unlike conventional insulation, Sound Control coatings significantly reduce corrosion under insulation (CUI)—which can cost your facility thousands a year in equipment and insulation replacement.

Lowering noise prior to its airborne release, our coatings also keep equipment viewable and safe for regular inspection. Call the ROST-COAT team today to learn more about how our cost-effective sound control solutions can benefit your manufacturing facility, plant or warehouse.